CHARGE AIR COOLING AND AIR COOLERS ON SHIP

Charge Air Cooling :

The air density determines the maximum weight of fuel that can be effectively burned per working stroke in the cylinder, it also determines the maximum power that can be developed by the engine.

The increase in air density is fractionally offset by increase in air temperature resulting from compression by turbochargers. Much of this potential loss can be recovered by charge air coolers. Charge air cooling has double effect on engine performance :

Condensation of moisture in the compressed air will occur during cooling and a drain is fitted to the outlet side to allow the condensate to be removed. The drain should be kept open and its discharge noted, this will also indicate if a cooling water leak has occurred......................................................................

.........................................................................................

..........................................................................

The air density determines the maximum weight of fuel that can be effectively burned per working stroke in the cylinder, it also determines the maximum power that can be developed by the engine.

The increase in air density is fractionally offset by increase in air temperature resulting from compression by turbochargers. Much of this potential loss can be recovered by charge air coolers. Charge air cooling has double effect on engine performance :

- By increasing the charge air density it increases the weight of air flowing in cylinder and

- by lowering the air temperature it reduces maximum cylinder pressure, exhaust temperature and thermal loading.

Condensation of moisture in the compressed air will occur during cooling and a drain is fitted to the outlet side to allow the condensate to be removed. The drain should be kept open and its discharge noted, this will also indicate if a cooling water leak has occurred......................................................................

.........................................................................................

| |

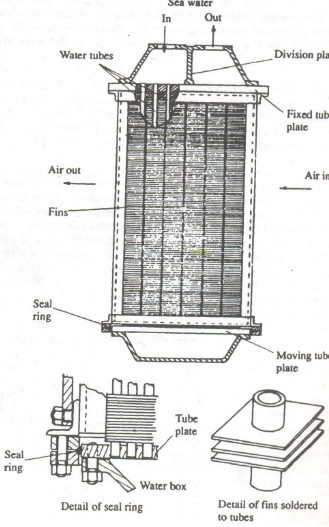

| Charge air cooler |

Comments

Post a Comment